|

|

|

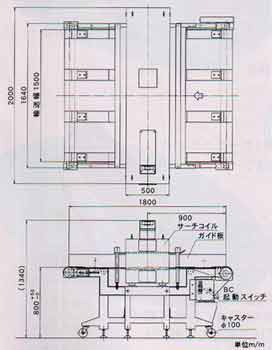

Conveyor mounted needle detector for wide products -

Two models are available to detect metal contamination in wide products.

- Flat search coil.

Search coil is mounted under the conveyor belt. this type of detector will detect needle contaminations in the product passing on conveyor.

- Tunnel type search coil.

Product is passed through the needle detection unit (search coil) mounted on the conveyor belt. Detection sensitivity of this type of metal / needle detector is very high not only for needles (made of ferrous material) but as well to contaminations made of stainless steel and variety of alloys, brass, aluminum, etc.

Features

- Reliable detection.

Stable, high sensitivity reliable detection.

- Easy operation.

Detection is carried out just by placing fabric on the conveyor belt.

- Self calibrating electronic control unit.

ND-820u evaluation electronics, include self calibration functions, this mean metal / needle detector will initially scan few times each product, analyze product characteristics, and automatically calibrate metal detector for the most optimum set-up.

Each setup is stored in separate memory location, and can be recalled during product change over.

Up to 200 product set-ups can be stored.

- Automatic Reporting. Each routine manual test of the needle / metal detector can be documented, and automatic report can be printed by the ND-820 control electronics.

Standard Specifications

MODEL |

|

| Effective detecting width:- |

1,500 or 2,000 mm

|

| Effective detecting height:- |

150 mm

|

| Belt speed:- |

20(50 Hz), 24 (60 Hz) m/min

|

| Length of conveyor:- |

1,800 mm

|

| Response to detecting contamination:- |

Conveyor stop automatically, issuing simultaneous audio and visual alarm.

|

| Supply voltage :- |

100 (220) VAC 50/60 Hz

|

| Power consumption:- |

Approx. 300 VA

|

Please contact us on info@jzw.com.au to discuss your application.

|

ND-757 conveyor mounted needle detector

ND-820U control electronics

ND-820U control panel

ND-757 conveyor mounted needle detector for up to 1,500 (2,000) mm wide product |